Heavy Machinery Undercarriages

RDW is one of Australia’s leading suppliers of heavy machinery and excavator undercarriages. We supply an extensive range of undercarriage parts and solutions for almost all makes and models. With extensive experience of supplying undercarriage and other heavy machinery parts since 1992, we know what parts provide superior value for money and are built to last.

All our undercarriage parts have been rigorously assessed for quality by our expert team. Our reputation as a leader in supplying well priced, premium quality equipment and parts is what keeps our happy clients returning year after year, and you have the peace of mind of knowing that the parts are warranted by a stable company that stands behind all that we do.

If you don’t see an undercarriage part or make that you are looking for listed on our website, we may still be able to help you. Our substantial stock holding covers machines from 4t – 250t for most makes and models of excavators, drill rigs, crushing and screening plants, including:

- Full undercarriage assemblies

- Idlers

- Sprockets

- Nuts and bolts

- Chain and Track Plate groups

- Link Assemblies, also known as track chains

- Top and Bottom (carrier) rollers

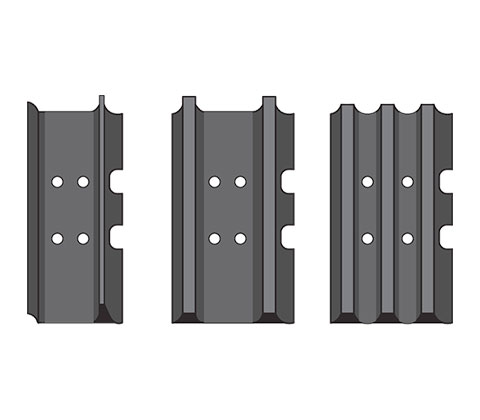

- Track plates in various dimensions and designs to suit the operating environment

All our undercarriage components have been sourced from companies leading the world in manufacturing Technology and are manufactured to high quality standards to meet the demands of tough Australian operating conditions in accordance with ISO9001 and ISO14001 standards.

Our product experts know to look at manufacturing tolerances, material selection and compatibility, product design, application and other key product attributes. Together with providing advice on what to replace and when, this helps ensure a long wear life and the lowest life cycle cost for our customers.

Our range includes products to suit:

- Caterpillar

- Komatsu

- Hitachi

- Volvo

- Case

- Hyundai

- Liebherr

- Yanmar

- Sumitomo

- Samsung

- Daewoo

- Doosan

- Kobelco

- John Deere

- Kubota

- Takeuchi

How to get your undercarriage to last longer

Apart from making sure that the undercarriage you buy is of a high quality and suitable for your application, there are ways to improve the life of your undercarriage, and the best part is that a lot of it doesn’t cost you much:

Remove dirt build up and Wash your machine – by keeping your undercarriage clean and free of dirt build up, abrasion is reduced so links and rollers last longer. The undercarriage will also be free to travel as it should. A clean machine allows you to identify any issues early, such as leaking seals that will cause premature wear.

Regular Maintenance – grease all lubrication points regularly, and check that the track adjuster is tensioning the tracks correctly. Tracks that are too tight or too loose will cause damage and shorten the life of the undercarriage.

Check your track plates – a rule of thumb is to replace your track plates before the top of the bolts start to wear. Ensure all track bolts and nuts are tight so there is no movement of the plate on the chain. Any track plates that are bent should also be replaced, as it impacts on the forces on the link assembly, rollers etc.

Avoid travelling long distances – excavators are not designed to drive long distances or at speed. This will cause the links and rollers to overheat and reduce their life. Try to plan the job so it can be done with short travel distances (which is also a more productive way of working) and use transport when needing to relocate the machine over longer distances.

Plan your undercarriage replacement – replacing for instance only one worn roller will mean that the life of the new roller will be reduced. This is because this roller will take more load, but also because it has to “wear in” to the existing wear pattern of the link assembly. For this reason, whilst it requires a larger investment, it is more economical to replace compatible sections of undercarriage, that is, full sets of rollers, or even the complete undercarriage. As each case is different, please talk to our experienced salespeople to work out the best solution for your needs.

What type of track plates should I use?

Machines have been designed to work best in “average” conditions, that is, the ground pressure etc is determined based on a compromise of many design considerations. When it comes time to replace undercarriage, most owners replace with the same width plates.

In some cases, such as where the ground is soft or swampy, wider track plates can be fitted so the machine doesn’t sink as much. When modifying your machine to use wide track plates, make sure you consider the following:

- Avoid rocky and uneven terrain. If the plates don’t sit flat on the ground, there will be twisting forces and point loads, which will shorten the life of the full undercarriage.

- The overall width of the machine will be increased, which may impact the width of the low loader required for transport and can create all the associated issues with wide load transport requirements.

Do you have to replace the link assembly and the track plates at the same time?

Depending on the operating environment, it is not uncommon for the track plates to outlast the life of the link assemblies/track chains. If the track plate is less than half worn (as measured from new lug height to the top of the bolt head), then it is often more economical to remove the existing track plates from the chains and reuse them on a new set of chains.

The removal and re-installation of track plates is best done on a track bench. Even though it might seem like a simple process, whether using new or used plates it is important to have the surfaces cleaned (paint removed etc) prior to joining plates to chains. Even more important is to have the nuts and bolts tightened to the exact torque settings using the correct tightening process. Getting any of these factors wrong will cause the plates to become loose, and cause damage throughout your undercarriage system.

How do I know what good undercarriage is?

Buying any product based on the lowest price rarely gives the best long term value for money. Buying your undercarriage from the original equipment manufacturer (OEM) of the machine is usually an expensive option. But there are ways of saving money without compromising on quality. Sometimes a particular brand of machine has exactly the same component as another brand of machine, but the dealers charge substantially different prices. OEM’s only know, and can only offer, their own OEM products – companies like RDW are not limited to only the OEM local supply source. Likewise, companies that push the “buy direct from the manufacturer” aspect only push one product, whereas a company like RDW not only has strong purchasing power, but we can modify our product offering so you get the best of each of the different components that make up the undercarriage, which may mean using multiple brands for the different portions. We know the strengths and weaknesses even within particular brand portfolios, so we will only sell the products that will meet the tough operating conditions in the Australian market.

Other options to OEM or “factory” products exist too. For example, the left and right hand side links supplied to chain manufacturers come from a finite number of foundries, some better than others, and they manufacture using more than one grade of steel. The companies that assemble the links brand their products under different labels, some under the Machine Manufacturer logo, some items leave under the link assembly manufacturers brand and others under whatever brand you prefer. Whilst all these products might come from the same factory, they may or may not be the same, as they can be ordered with for instance different brands of seals. So even if you think you are getting the same brand of product, you may not be getting the same quality. The cheaper seals might be fine in for instance a farming application where hours per year are very low and soil conditions are easy but won’t hold up in a construction environment. This is why in some cases prices and quality for what you think is the same product can still vary quite considerably, and why it is imperative to buy only from companies that you trust to know our industry and your requirements.

The undercarriage you buy is only going to be as good as the company you buy it from. It is important that the company you purchase from has a long standing reputation of supplying undercarriage to suit Australian conditions, and that they will stand behind the product you buy. RDW Excavator Parts as an excavator specific specialist has been providing parts and servicing of Excavators in the Australian market since 1992, and being a 100% Australian privately owned business, we will be here for many years yet.

The above highlights why it is important to discuss your undercarriage with an independent parts supplier, not just the OEM. That’s why it is so important to talk to specialists such as the people at RDW, because we know what fits what, and will help you get the best value for your particular needs.